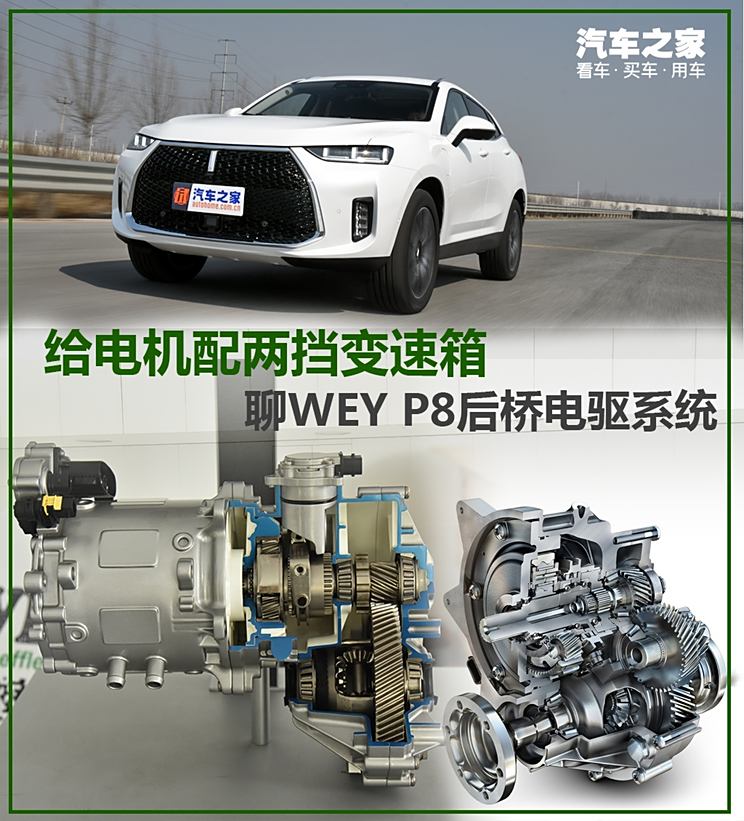

Discussion on WEY P8 rear axle electric drive system with two-speed gearbox

[Interpretation of car home’s fresh technology] With the development of electrification, more and more automobile manufacturers are considering replacing the traditional engine with motor drive. However, for plug-in hybrid SUV, the role of motor must be diversified, not only to drive the vehicle, but also to help the vehicle realize the four-wheel drive function and help the dynamic performance of the whole vehicle at all times. Based on the above requirements, Schaeffler put forward a solution, which is used for the two-speed electric drive axle with P4 frame. To put it bluntly, a motor is installed on the rear axle, but the highlight is that it is equipped with a two-speed reducer for this motor. At present, this product has been installed on Changan CS75 PHEV and (|). Today, let’s see if it is unnecessary to do so.

Read the full text in a few minutes:

1. Putting an electric drive axle on the rear axle can make the plug-in hybrid SUV realize the four-wheel drive function;

2. The Schaeffler two-speed electric drive axle has been mass-produced in Changan CS75 PHEV and WEY P8;

3. The natural special effects of the motor determine that it can use a reducer with a fixed speed ratio, but the fixed speed ratio will reduce the high-speed dynamic performance of the vehicle, and the bridge can not give more help to the vehicle in the four-wheel drive mode.

4. Schaeffler’s two-speed electric drive axle is equipped with a two-speed reducer, which brings better acceleration performance, more efficient economy and meets the complex mode of hybrid vehicles;

5. The modular design of Schaeffler electric drive axle can adapt to different models and platforms.

1. What is an electric drive axle?

When it comes to traditional fuel vehicles, everyone knows that there are engines and gearboxes, and when it comes to electric vehicles, there are motors and battery packs. However, electric drive axle seems to be a strange word. In fact, it is the name of a system. It can integrate motor, reducer, differential and electronic control system to realize the electrification of the drive system. According to the different installation positions, it is placed on the front axle or rear axle of the vehicle to realize the pure electric drive of the front wheel or rear wheel. It can also be applied to pure electric vehicles, hybrid or plug-in hybrid vehicles according to different vehicle types.

Using rear axle electric drive to realize four-wheel drive can save a lot of space and weight, make room for battery pack, and also save the cost of transfer case and transmission shaft. At present, this method of placing the electric drive axle on the rear axle is widely used in plug-in hybrid SUVs. For example, BYD Tang 100 adopts P034 frame, Changan CS75 PHEV adopts P134 frame, and Great Wall WEY P8 adopts P04 frame.

Second, does the motor need a two-speed reducer?

Changan CS75 PHEV and WEY P8 are equipped with Schaeffler two-speed parallel-axis electric drive axle. From the name, we can see the characteristics of this electric drive axle. One is that it has the function of shifting gears, and the other is that it adopts the layout of flat shaft.

During high-speed cruising, or overtaking, the pure electric vehicle is a little weak, and the motor keeps a high speed at this time, because it does not operate in the most efficient working range, and the efficiency of the motor is not as good as that of the internal combustion engine. At this time, you can add a gear to the reducer of the motor and pull the speed of the motor back to the constant torque area. In this way, the dynamic performance of the vehicle can be improved and the economy can be improved.

Seeing this, someone must say that since the two-speed reducer is so good, why not use pure electric vehicles? Because for most pure electric vehicles, the ultimate capacity is not the first. Moreover, pure electric vehicles can make up for the lack of fixed gear ratio reducer by selecting motors with high power density and high speed and excellent electronic control system.