It’s windy-past lives in power exchange mode

On June 6th, the National Development and Reform Commission, the Ministry of Ecology and Environment, and the Ministry of Commerce once again pushed the development of new energy vehicles-"Implementation Plan for Promoting the Updating and Upgrading of Key Consumer Goods and Smooth Resource Recycling (2019-2020)" was released. The importance of this document can basically be understood as the main theme of the post-new energy vehicle era. That night, we took a look at the dynamics in the circle, which is roughly like this:

From a fundamental point of view, this is a promotion document for digesting production capacity nationwide, which is good for all companies in all industries, large and small. On the other hand, the switching of fuel vehicles in China is the icing on the cake. However, this Dragon Boat Festival, the vast majority of car companies and pile companies have spent a uneasy festival. To sum up, people who have no long-term worries will have near worries.

From the point of view of energy supplement, there are several points worthy of attention in this document: how to go in the future in the process of changing tracks from policy-driven to market-driven in China’s new energy automobile industry.

one

Gradually realize battery platformization and standardization.

Prepare for modular car building, dynamic circulation of power batteries and ladder utilization, and do not rule out the possibility of introducing unified standards for power batteries in the future.

2

Vehicle-electricity separation

Reduce the threshold for car purchase in the post-subsidy era, activate the enthusiasm of new energy vehicles, and protect the stable development of the industry.

three

Develop new energy vehicle products with combination of charging and replacing electricity, flexible configuration and long driving range.

1. The energy supplement system adds electricity exchange, providing a new solution in terms of energy supplement efficiency. 2. The power battery can be configured flexibly after modularization to meet different travel scenarios and demands.

four

Smooth the whole life cycle of resources and improve the utilization efficiency.

The specification for step utilization, disassembly and scrapping of power batteries has entered the research stage.

Judging from the logic of the new energy automobile industry in the full text of the policy, it mainly guides the industry from two aspects: encouraging the upstream and downstream of the new energy automobile industry to continue research and development, promoting cost reduction and efficiency improvement, perfecting the energy supplement system and improving the market application of new energy vehicles. The document specifically mentions that it is necessary to learn from the power exchange mode and application experience in the field of public services, and encourage enterprises to develop new energy vehicle products with the combination of charging and power exchange, flexible battery configuration and long driving range. Therefore, we feel it is necessary to show past lives, the power exchange mode, to everyone.

01 Sadness Xia Jiaxi and His Better Place

In 2007, Shay Xia Jiaxi put forward the power exchange technology, and then founded a power exchange company called Better Place in Israel. After the financing of $850 million was changed in 2013, Xia Jiaxi and his dream of Better Place collapsed. Even though the valuation reached an unprecedented $2.25 billion at that time, the hopeless power exchange model was ruthlessly abandoned by capital.

Xia Jiaxi’s Ambition and the Legacy of Better place

In the early days of its establishment, Xia Jiaxi foresaw that the power battery, a key component that directly affects consumers’ desire to buy, would not improve by leaps and bounds in the short term. The most direct way to solve the mileage anxiety is to form the same energy supply efficiency as fuel supply for fuel vehicles. The energy supplement market bred by the emerging industry of electric vehicles will directly subvert the existing energy structure and consumption mode. Under such a market positioning setting, Xia Jiaxi boldly left SAP.

One year after the establishment of Better place, Israel’s first "power exchange station" was established. First, it signed a cooperation agreement with Renault to provide 100,000 Fluence ZE electric vehicles (but the actual order was less than 1%). Better Place started with 750 drivers in Israel, and the charge for electricity exchange service includes battery rent and electricity exchange fee. Although the hardware cost, battery maintenance cost and education cost of consumers and enterprises were incomprehensible at that time, Xia Jiaxi did not hesitate to continue to burn money in Denmark and the United States, but at that time, car companies still had great doubts about the development of new energy vehicles, and the convenience and use cost of customer-side power exchange mode were not particularly different from those of traditional fuel vehicles. Better Place only launched thousands of vehicles around the world until it was closed.

The end of the road for Better Place seems to be ill-timed now. After all, the overall environment of the new energy automobile industry is far from the same. However, Better Place has left a complete chassis power exchange technology for future generations, and the value generated by the experience in the operation process is immeasurable.

Schematic diagram of Better Place power exchange station and power exchange

02 Phased tasks of State Grid

863 Program-the Beginning of Power Exchange Technology

In 2006, the domestic electric vehicle industry was still in its infancy. The State Grid responded to the call of the country to start the electric vehicle project, and Zhejiang Power Grid is the top priority to implement the project. At that time, the first project leader of Zhejiang Power Grid participated in the project was Mr. Nie Liang (the first person in the domestic market application field of power exchange mode). In 2010, his team developed and completed the first licensed pure electric vehicle in China, and completed the reserve of basic power exchange technology. In the same year, Nie Liang was responsible for building the Zhejiang project of intelligent charging and replacing power service network. Different from Better Place, a pioneer in power exchange, State Grid developed a set of standard box power exchange technology after understanding the chassis power exchange technology. In Hangzhou, 500 power exchange taxis were piloted with Langyue and Prima models and high box standard boxes, and the business model of "separation of vehicles and electricity and mileage charging" was put forward and verified for the first time in this project.

Power exchange stations and standard boxes piloted by State Grid in Hangzhou

It can be said that the power exchange technology was basically a system at that time, and the pilot effect was quite satisfactory. Later, the Beijing-Shanghai trip organized by State Grid set a fire for the development of power exchange. What’s more interesting is that. In August 2010, State Grid joined the "China Enterprise Electric Vehicle Industry Alliance" and served as the chairman of the charging and service professional committee. At that time, State Grid determined the basic idea of its own intelligent charging and replacing operation mode, that is, mainly replacing electricity, supplemented by plug-in, centralized charging and unified distribution. In other words, the development direction of state grid is to change power stations, not. In line with the above development ideas, State Grid also reserves advanced technologies such as battery balancing, battery automatic replacement equipment and battery cascade utilization. These forward-looking explorations and pre-research have laid a solid theoretical foundation for the budding electric vehicle industry, pointed out the general direction of technical development, and established the development path and ideological system of the whole industry. Today, these technologies have been widely used, especially the chassis replacement mode and standard battery box technology, which have become the mainstream of domestic electric vehicles. However, during 2013 -2014, State Grid did suspend the project of replacing new energy vehicles with electricity due to the change of the main task direction of enterprises. We inquired about the relevant historical information and found that apart from the change of the main tasks of enterprises, the irreconcilable contradiction with car companies is also one of the development factors that hinder their power exchange mode. After all, no car company is willing to become a subsidiary of State Grid. At that time, a director of the National Development and Reform Commission once said: "State Grid should put its position right and cooperate with car companies to develop electric vehicles with a more open attitude."However, State Grid’s insistence on the power exchange mode is not only not conducive to its stable position in the electric vehicle infrastructure market, but also more likely to restrict the development of electric vehicles. In other words, the failure to get through the industrial chain has become the biggest factor for the grounding of the State Grid’s power exchange model. On the other hand, the national policies at that time, such as subsidies and the environment of new energy vehicles, were still relatively weak. Therefore, although the State Grid ran through the business model of power exchange, it was unable to open up the industrial chain to form a business ecology due to institutional factors, and it was inevitable to suspend the power exchange project.

03-The sharing mode has no future.

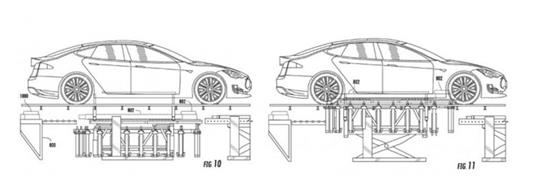

After the State Grid froze the power exchange mode, Tesla, an American star company, demonstrated its 90-second quick exchange technology in 2013, once again detonating the problem of changing the phone all over the world, but soon Tesla will develop specifically for supercharger 3. From a technical point of view, Tesla still follows the chassis power exchange idea of Better place, but it is further improved in speed. But when "Iron Man" saw the fatal defect of chassis-type power exchange-abnormal batteries can not be shared across car models, and the compatibility of power exchange stations is low, so low compatibility can not improve operational efficiency. It is even more unrealistic to integrate the resources of car companies and form a common standard. In such a complicated power changing environment, Tesla silently quit to change the power stage.

Schematic diagram of Tesla power exchange technology

The rise of 04 module box-splitting power exchange technology

In 2014, Nie Liang left the State Grid after seeing the possibility of opening up the industrial chain of the power exchange system and constructing the power exchange ecology. In the same year, Hangzhou Botan was established, and based on the power exchange of State Grid, the low-box standard box battery was further developed. Compared with the standard box of State Grid in 2010, the low-box standard box battery can be directly placed in the vehicle chassis (the original high-box standard box battery of State Grid needs to be placed under the back seat of the vehicle or in the trunk of the vehicle), and the stability and safety of the vehicle are greatly improved. On the other hand, at that time, the large-scale travel business began to exert its strength, and the market segment paid unprecedented attention to the operation economy of fuel and new energy vehicles. The split-box power exchange mode combined with the large-scale travel business perfectly solved the problems of operating costs and energy replenishment efficiency, and the module split-box power exchange ushered in its historical opportunity.

Standard charging cabinet and standard box batteries for module box-changing.

So, what is the principle of module splitting? First of all, the main dimensions of the TEU are completely the same, but according to the iteration of power battery technology, the energy density can be continuously improved. At present, the single TEU is mainly 15KWH (see the figure below). According to the requirements of vehicle models, different numbers of TEU power batteries are arranged on the vehicle chassis (2/4 for passenger cars and 6 or even 8 for logistics vehicles). Because the box size is the same at the initial stage of design, the power exchange station can exchange power for all vehicles using TEU, no matter which main engine factory they are made, thus completing the development of three limited power exchange modes: compatibility of power exchange equipment and vehicle models, compatibility of charging equipment with TEU, and recycling of circulating batteries.

Box size (mm)

825*500*130

Capacity (Ah)

127

150

185

Voltage (v)

80

Electricity quantity (Kw.h)

10

twelve

15

Weight (kg with glue)

Less than 95kg

Less than 100kg

93/100kg

polymer

academic titles conferred on the three candidates who came out first at examinations held at three levels

energy density

109.47

120.65

160/150

05 Inventory of Power Exchange in China at the Present Stage

In 2016, the chassis replacement technology that sank for a period of time reappeared in the field of vision. This time, Cai Dongqing created Shanghai Aodong New Energy Automobile Technology Co., Ltd., and made continuous efforts in the power replacement business, and then quickly followed up. Sort out the development path of domestic power exchange technology, which is roughly as follows:

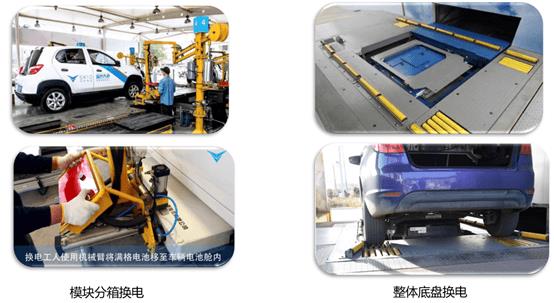

Mainstream power exchange technology: module splitting and chassis power exchange, as shown below:

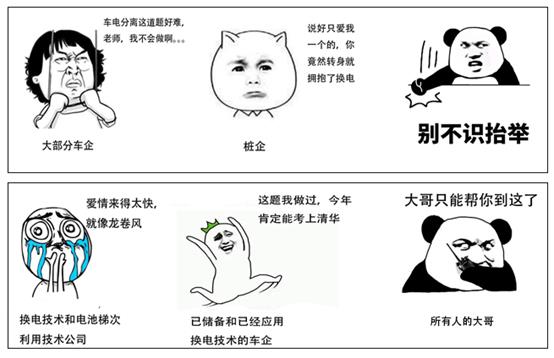

It is worth noting that at present, the two modes of automatic route for power exchange are slightly different. Six-axis robots are mainly used for power exchange in modules, and RGV is mainly used for chassis change, which is roughly as follows.

Market application: Beiqi Weilai Xinchufeng is used for chassis power exchange, Dongfeng, Zotye, Universiade are used for module power exchange, and the number of vehicles put in and the actual mileage of operation are slightly superior.

How to compare the above two power exchange technologies?

We believe that it is not objective enough to compare the above two power exchange technologies only from the actual promotion layout level (such as infrastructure investment, power exchange capacity, site requirements and construction speed, etc.). The reason for this is the following:

Equipment level: manual, semi-automatic or full-automatic power exchange mode can also be selected for box-by-box power exchange, and the investment intensity can be selected according to the actual situation, while chassis power exchange can only be fully automatic, so it has higher capital requirements and limited investment flexibility in practical promotion. However, according to the fully automatic standard, the cost difference between RGV and six-axis robot equipment is not big.

Site expansion level: the chassis can be quickly laid out in containers for power exchange, and the landing speed is slightly faster, but some cities are not allowed to work in containers (such as Guangzhou). Therefore, in terms of policy compliance, the requirements for the construction of sub-box power exchange and chassis power exchange are basically the same.

On the aspect of power exchange capacity: in the fully automatic state, the average daily power exchange capacity can reach about 250 times with little difference. However, there is a point of concern in this respect. According to the public data, although there are more charging compartments in the power exchange stations with the same power exchange capacity, the number of vehicles that can be exchanged for electricity is only slightly more or equal to that of the chassis (we think that the future evaluation of power exchange capacity can not only rely on the single angle of power exchange speed, because the power exchange capacity depends on the number of charging compartments in the station energy supply, From this point of view, the general modular sub-box power station has 120 cells at the same level, while the chassis power station has 28 cells. However, one car in the modular sub-box power station consumes 4 cells on average, so the power exchange capacity of 120 cells, that is, 30 cars at a time, is not much different from that of the whole pad chassis power station with 28 cells. Therefore, there is little or no difference between the two modes from the above three aspects, so there is no way to compare them only from these three points.

With the issuance of the document "Implementation Plan for Promoting the Updating and Upgrading of Key Consumer Goods and Smooth Resource Recycling (2019-2020)", on the basis of encouraging the development of power exchange mode, requirements are put forward for battery modularization and step utilization of batteries. Therefore, which mode can be compatible with more types of vehicles, better connect the front and rear ends of battery step utilization and better adapt to the future modular development of automobile manufacturing is the more important focus.

From the perspective of vehicle compatibility, the power exchange mode should not be a limited energy supplement scene in the end, but an open source energy supplement mode, because the most basic and basic construction purpose of the power exchange station is to be used as a public infrastructure to facilitate public travel, otherwise why do you enjoy subsidies? At present, Beiqi, Weilai and other car companies are leading the chassis power exchange, because the batteries of their respective car companies are opposite-sex batteries compared with other OEMs, the power exchange sites or batteries cannot be universal. However, Dongfeng, Universiade, Zotye and other enterprises adopt the idea of modular box-splitting power exchange based on standard box batteries, which makes the power exchange station shared among different car models, and the battery can be shared, which greatly improves the utilization ratio of the site and the battery. Therefore, from this perspective, it is obvious that modular box-splitting power exchange is more suitable for the current concept of "sharing economy" and is also an intensive use of social resources.

From the point of view of power battery recycling, the mainstream design ideas in the industry at present are as follows

Direct view of step utilization of power battery

From the point of view of echelon utilization, we must first reduce the transformation cost in the process of each degradation, otherwise it will be difficult to land. From the top-level design point of view, the standard of battery should be unified first, and then the battery with smaller relative weight and volume (because it can’t be directly used in section B and section C if it still stays in the direction of the overall special-shaped battery of most models at this stage). Only under these two preconditions can the whole life cycle development of battery be maximized, and the average use cost of power battery at the user’s end will be lower.

Therefore, from the perspective of battery recycling, it is obvious that the case-by-case power exchange built by the standard box system is more in line with the policy and national conditions. However, from the perspective of automobile enterprises, the whole chassis-type power exchange has less changes to the chassis of the whole vehicle body, and the technical level is relatively easier to realize; However, the modular box-changing technology requires higher requirements for body chassis modification and design cycle. However, it is very interesting that the number of car companies that accept the standard box-splitting power exchange system is far more than that of the chassis-type power exchange model (the total number of cars that are actually put in the box-splitting power exchange system is also more than that of the chassis-type power exchange system). It can be said that many car manufacturers are doing power exchange, and obviously many car companies do not want to play with tickets at this level, but stand higher and look farther.

07 written at the end

On June 5, 2016, China Tower established an energy company with a capital of 5 billion yuan to take the lead in entering the terminal market of power battery ladder utilization, which made it possible for standard box batteries used by modular box-changing electric vehicles and power-changing technology companies to be used in large-scale terminals (compared with special-shaped batteries). The integrity of power battery ladder utilization has been further improved, while the extension of battery ladder utilization industrial chain has further reduced the average use cost of power batteries, which will indirectly reduce the consumption cost of new energy vehicles. From the perspective of industrial chain, does it mean modularity?

We gave time to this problem, but for enterprises that insisted on changing electricity in the early stage, in June 2019, the wind started.